Common Applications

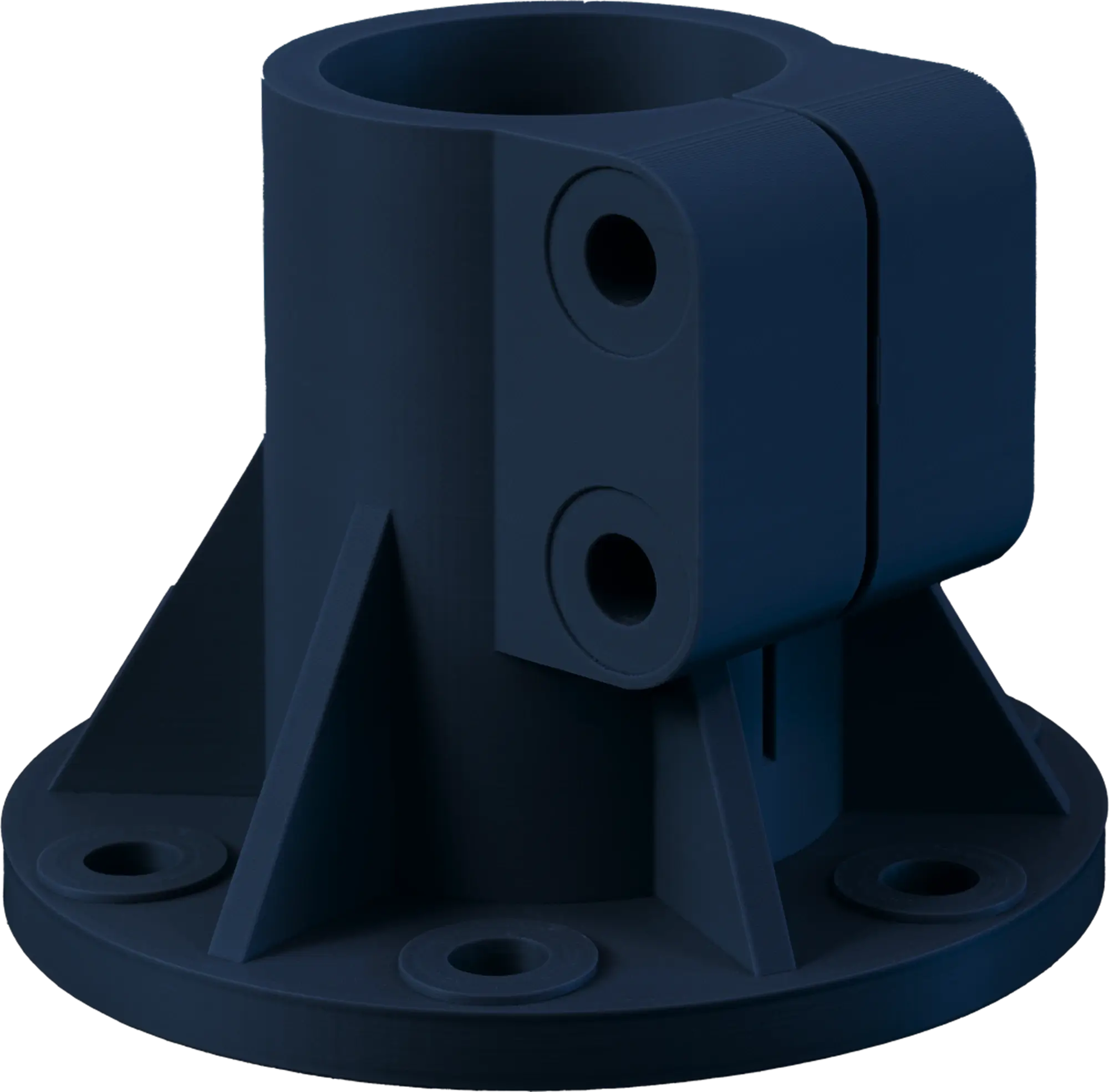

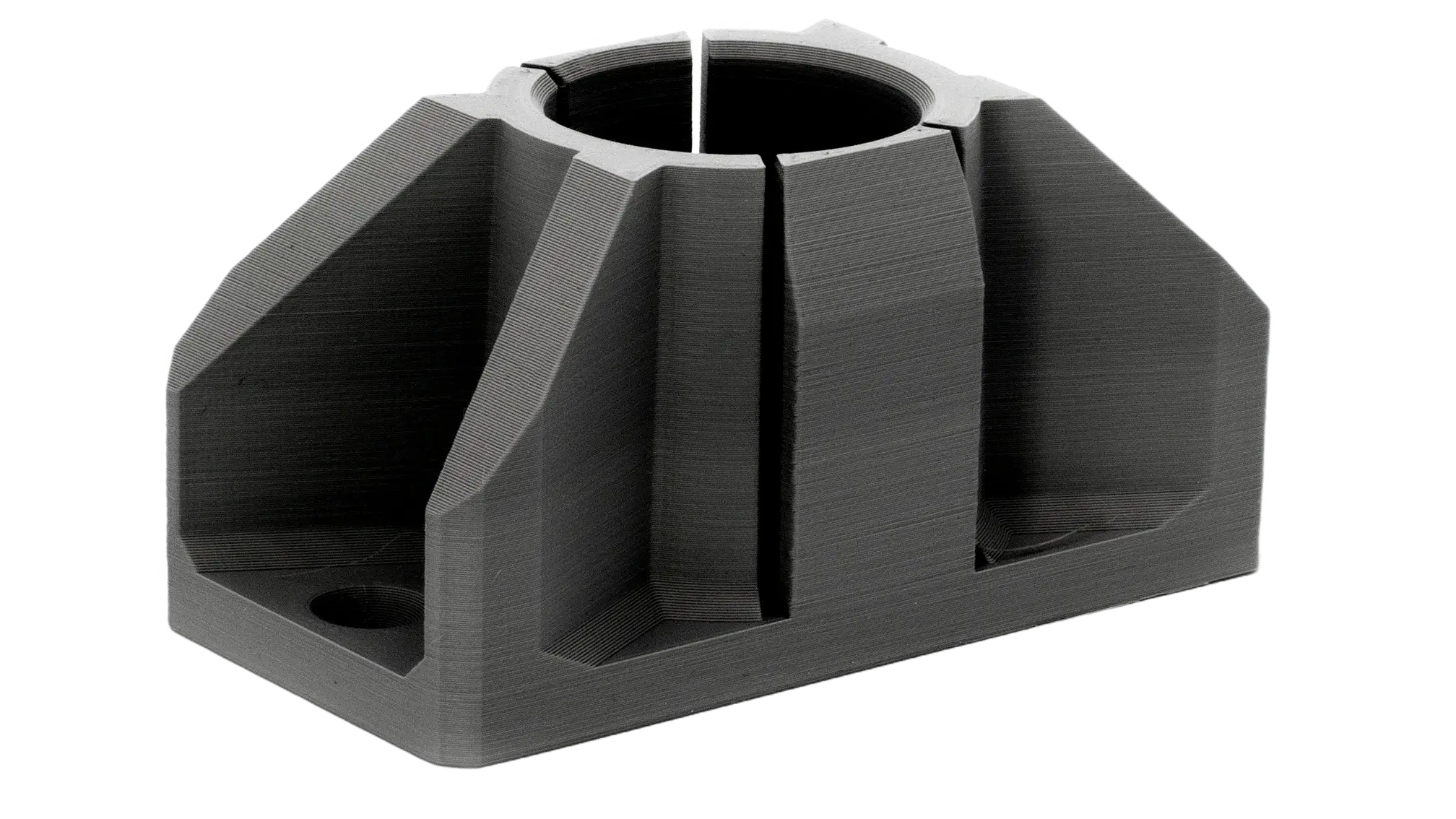

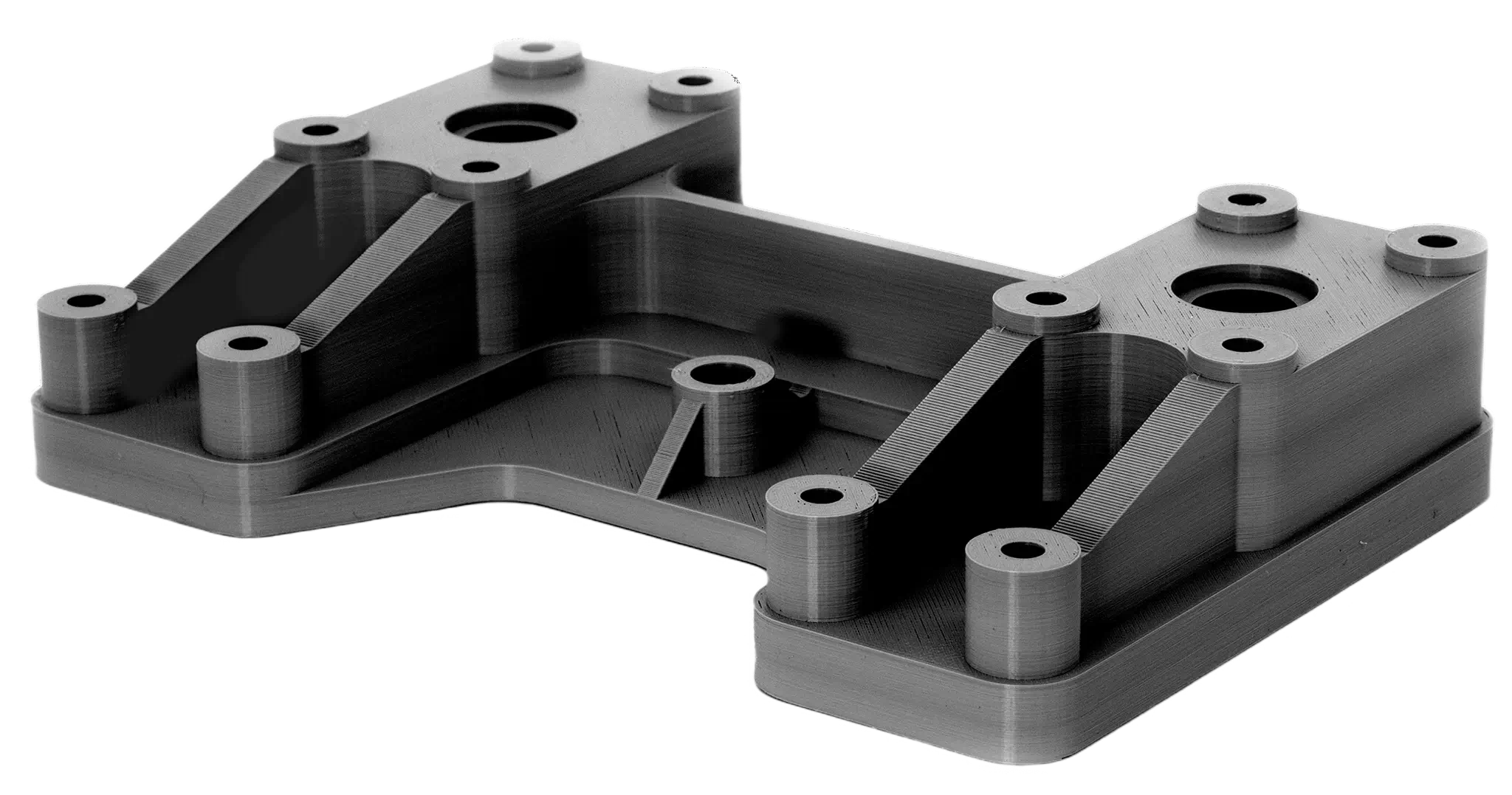

- Automotive & electronic parts

- Strong and durable outdoor products

- Technical and functional components like gears

- Testing equipment, technical device casings, motor or drone protectors

Advantages

- Extremely strong and impact resistant

- High temperature resistance

- Weather resistant

- Higher production costs

Disadvantages

- Susceptible to certain chemicals

Colors

General Specifications

| Property | Value |

|---|---|

| Printing Temperature | 260 - 310°C |

| Bed Temperature | 100 - 120°C |

| Shrinkage Rate | Medium (1.9%) |

Physical Properties

| Property | Test Method | Value |

|---|---|---|

| Density | ISO1183, GB/T1033 | 1.12 g/cm³ at 23°C |

| Melt Index | 300°C, 1.2 kg | 19.5 g/10min |

| Light Transmission | N/A | N/A |

| Fire Resistance | N/A | N/A |

Chemical Resistance

| Effect | Value |

|---|---|

| Effect from weak acids | Fair |

| Effect from strong acids | Not resistant |

| Effect from weak bases | Fair |

| Effect from strong bases | Not resistant |

| Effect from oils and lubricants | N/A |

Thermal Properties

| Property | Test Method | Value |

|---|---|---|

| Glass transition temperature | DSC, 10°C/min | 113°C |

| Melting temperature | DSC, 10°C/min | N/A |

| Crystallization temperature | DSC, 10°C/min | N/A |

| Decomposition temperature | TGA, 20°C/min | >360°C |

| Vicat softening temperature | ISO 306, GB/T 1633 | 116.9°C |

| Heat deflection temperature | ISO 75 1.8MPa | 99.3°C |

| Heat deflection temperature | ISO 75 0.45MPa | 114.1°C |

Mechanical Properties

| Property | Test Method | Value |

|---|---|---|

| Tensile Strength (X-Y) | ISO 527, GB/T 1040 | 54.88 MPa |

| Elongation at Break (X-Y) | ISO 527, GB/T 1040 | 150.24 % |

| Flexural Modulus (X-Y) | ISO 178, GB/T 9341 | 1073 MPa |

| Flexural Strength (X-Y) | ISO 178, GB/T 9341 | 63.41 MPa |

| Charpy Impact Strength (X-Y) | ISO 179, GB/T 1043 | 13.2 kJ/m² |

Last updated: 6/15/2025